Diamond Wheel

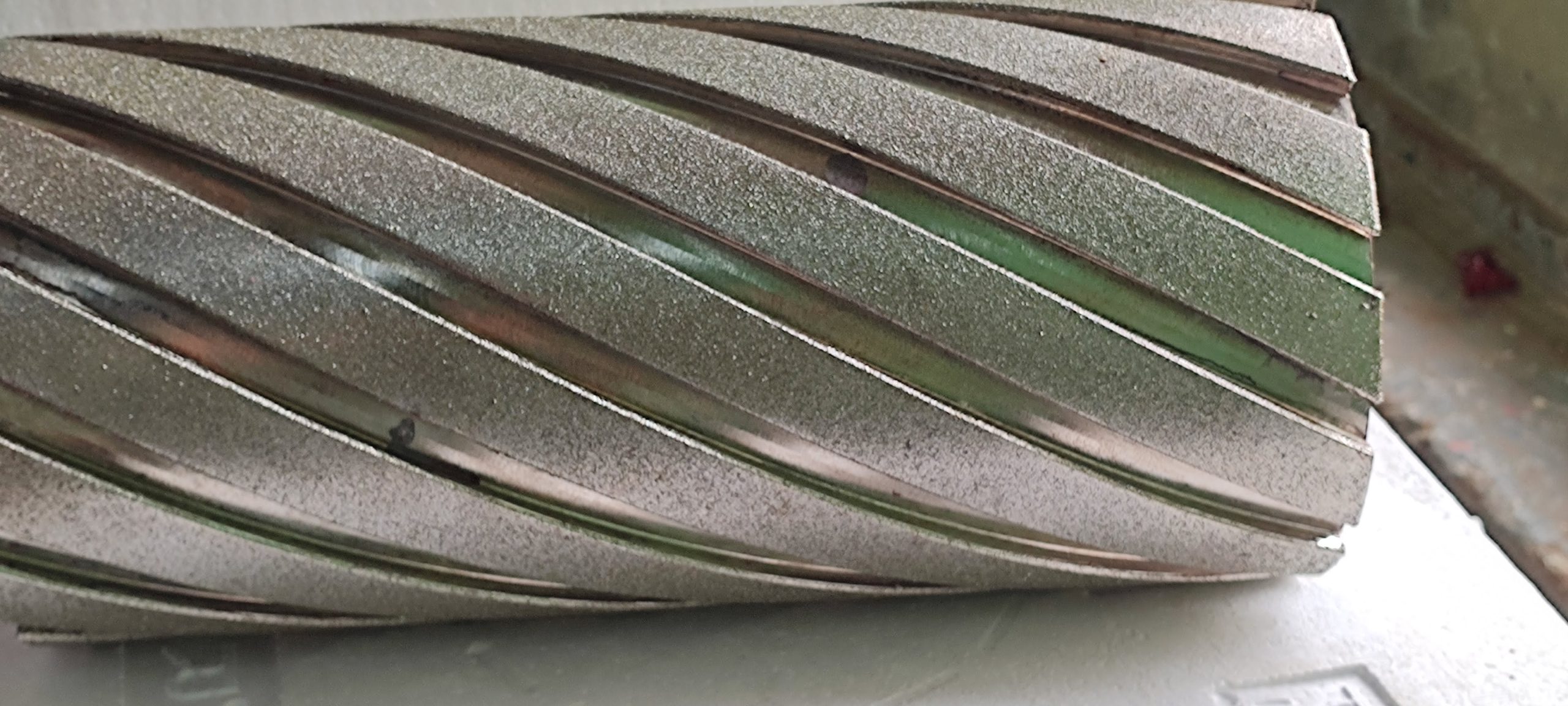

Electroplated Diamond Wheel:

Sanco is a specialist in the Design and Manufacture of Electroplated Grinding wheels, Pins, Saws and specialized Tools using both Diamond and CBN abrasives. Our Customers range from Surgical Needles and Aerospace manufacturers to suppliers of Fiberglass oil pipe Industries and Military applications. Our speciality is, we can do any products related to diamond cutting wheels, grinding wheels arrange from 1” to 50”

Our range of Electroplated Diamond Products are:-

Cut off wheel 1”-50”

Od and Id grinding wheel

Hand file

Core drill

Countersink tools

Spl purpose tools

As per customer requirements.

Resin Bonded Products

Resin bonded tools have a high grinding efficiency that gets the job done quickly. Resin Bond is also good at self-sharpening for prolonged use before maintenance is necessary. One attractive quality of Resin Bonded Products is the inherent tendency to maintain Low Temperatures under use. This lowers the danger of burning an expensive work-piece in the process of Grinding or Polishing. Resin bonded tools are also less apt to experience Loading, and they Dress easily for added convenience.

The bonding of our Resin Bonded Grinding Tools helps to improve the overall finish of each ground tool. Whether you need polishing, sharpening, light or heavy grinding, our Resin Bond Products will meet your expectations.

Metal Bonded Products

Metal bonded tools are created from the sintering of powdered metals and other compounds with either diamond or Cubic Boron Nitride (CBN). This process produces an extremely strong product that holds its shape well during use. Metal bond maintains a long and useful tool life with a reduction in the frequency of dressing. Our Metal Bonded Products can be used in Dry/Wet grinding, our Wheels, Core drills and Grinding Tools work well on multiple surfaces including Ceramics, Glass, Quartz, Silicon, Refractories, Semi-conductors, and Optic materials.

Whether employed for Creep feed, Internal, form, Tool cutting, or Glass and Ceramic grinding, a Metal bond Tool will give the longest quality service before routine maintenance is required.

Brazed Tools

This unique technology of manufacturing single layer diamond & CBN tools offers numerous advantages in the production of custom made profile tools for the Metalworking, Composite, Ceramics and Stone grinding industries. In this technology a special bond is used in order to manufacture a tool in a vacuum cell at a high temperature.

The line of products includes Profile tools for the Fiberglass and Reinforced plastics Industries, Routers for grinding composite in Aerospace industry, Tools for cutting and grinding Composite in Ship building industry, Tools for Cutting and Profile composite in Automotive industry and Diamond routers in various shapes for the stone and Marble industry.

The main advantages of "SANCO" vacuum brazed tools are:

- Flexibility in the manufacturing process enables us to manufacture small series which include one-of-a-kind tools at reasonable prices.

- The possibility to place Diamonds selectively. This permits the production of various tools where application demands varying concentration of Super abrasives.

- The ability to create tools utilizing different grit sizes and qualities on the same tool so that new type of tools can be made. The ability to vary concentration and depth of super abrasives embodiment enable the production of optimal, Cool running, Free Grinding of tools capable of higher load factors.